M81824

M81824 Crimp Splices

The D-436 crimp splices are a MiniSeal high-performance immersion-resistant Crimp Splice. Consists of plated copper crimp barrel and a separate, heat-shrinkable, transparent sealing sleeve made from radiation cross-linked polyvinylidene fluoride. This environment-resistant splices provides excellent reliability, long term performance, mil-spec qualification and a low installed cost.

- Small Size

- Lightweight

- Insulation and Strain Relief

- Easy to Install

Applications

Defense, Military & Aerospace

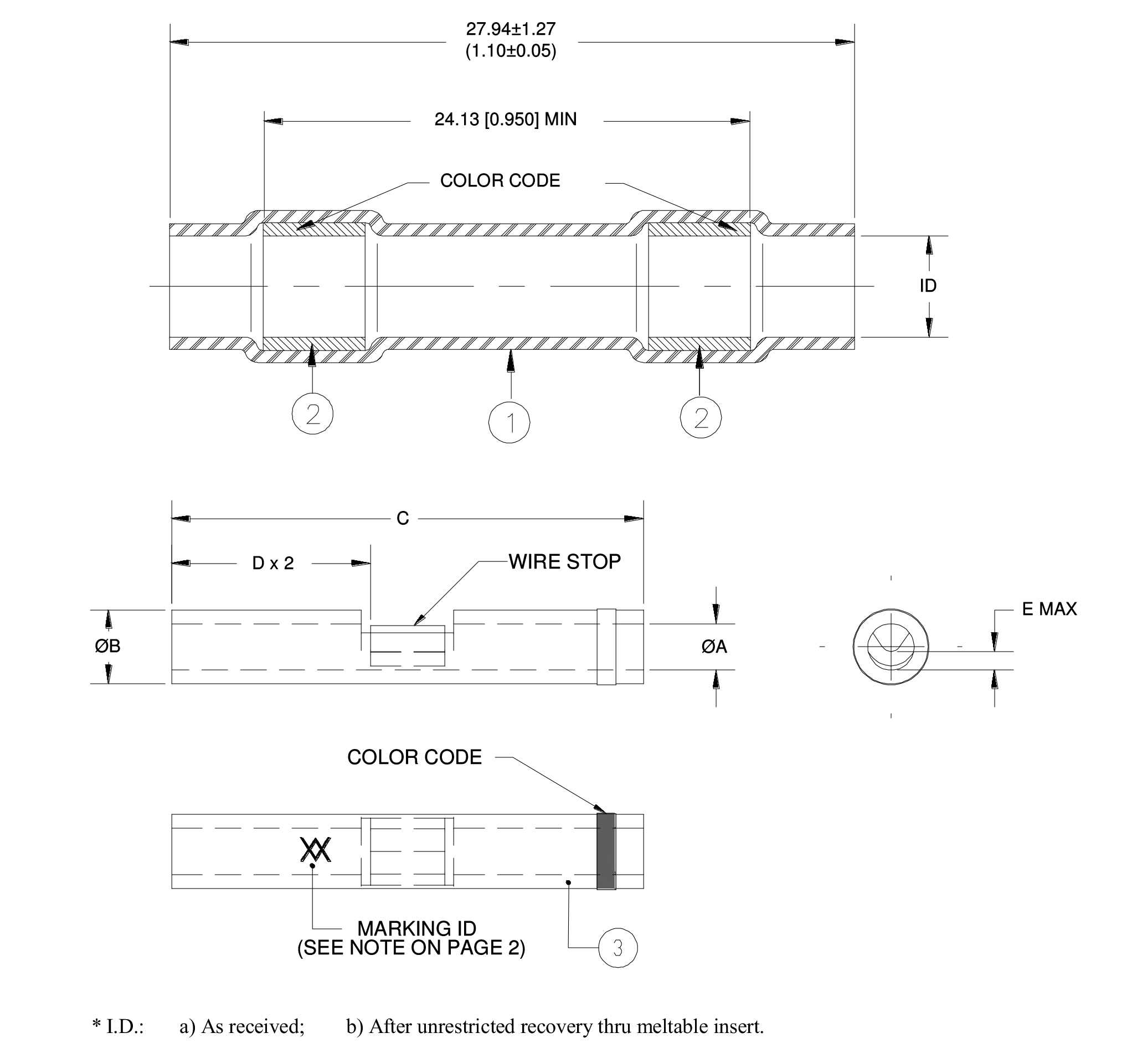

TABLE I – DIMENSIONS

| Part Name | I.D.* a. min • b. max | Crimp Splicer ºA | Crimp Splicer ºB | Crimp Splicer C | Crimp Splicer D | Crimp Splicer E max | Crimp Splicer Color Code | Crimp Splicer Wgt. Lbs./Mpc max |

|---|---|---|---|---|---|---|---|---|

| D-436-36 | 2.16 (0.085) | 1.27 (0.050) | 2.03 (0.080) | 12.95 (0.510) | 6.22 (0.245) | 0.38 | Red | 1.02 |

| 0.64 (0.025) | 1.14 (0.045) | 1.91 (0.075) | 12.45 (0.490) | 5.72 (0.225) | (0.015) | Red | 1.02 | |

| D-436-38 | 2.79 (0.110) | 1.75 (0.069) | 2.70 (0.106) | 14.86 (0.585) | 7.11 (0.280) | 0.51 | Blue | 1.61 |

| 0.64 (0.025) | 1.63 (0.064) | 2.57 (0.101) | 14.35 (0.565) | 6.60 (0.260) | (0.020) | Blue | 1.61 | |

| D-436-38 | 4.32 (0.170) | 2.60 (0.102) | 3.89 (0.153) | 14.86 (0.585) | 7.11 (0.280) | 1.27 | Yellow | 2.72 |

| 0.64 (0.025) | 2.46 (0.097) | 3.73 (0.147) | 14.35 (0.565) | 6.60 (0.260) | 0.050) | Yellow | 2.72 |

TABLE II RECOMMENDED WIRE RANGE BASED ON CONDUCTOR CMA (mm2) (REFERENCE)

| Part Name | Mil Spec Equivalent Size | Single Wire | Multple Wire Range CMA (mm2) | Multiple Wire Total OD (OD, +OD2) Max |

|---|---|---|---|---|

| D-436-36 | M81824/1-1 | 26-24-22-20 | 304 - 1510 (0.15 - 0.75) | 0.085 (2.16) |

| D-436-37 | M81824/1-2 | 20-18-16 | 1058 - 2680 (0.53 1.34) | 0.110 (2.79) |

| D-436-38 | M81824/1-3 | 16-14-12 | 2375 6755 (1.19 3.37) | 0.170 (4.32) |

TABLE III STANDARD CONDUCTOR CMA (REFERENCE)

| Size | Size | Size | Size | Size | Size | Size | Size | |

|---|---|---|---|---|---|---|---|---|

| Conductor Configuration | 26 | 24 | 22 | 20 | 18 | 16 | 14 | 12 |

| Strands | 19 | 19 | 19 | 19 | 19 | 19 | 19 | 37 |

| CMA | 304 | 475 | 754 | 1216 | 1900 | 2426 | 3831 | 5874 |

| (MM2) | (0.15) | (0.24) | (0.38) | (0.61) | (0.95) | (1.21) | (1.92) | (2.94) |

APPLICATION

1. These parts are designed to provide immersion resistant in-line splices, maximum of two wires per side of crimp and falling within

the diameter range specified in this customer drawing, and having insulations rated for 135°C.

2. Parts will meet all requirements of SAE AS81824/1 when installed as outlined below. Assembly is not required for

acceptance testing inspection.

3. Acceptance sampling shall be in accordance with Paragraph 4.6.1 of AS81824Tm.

4. Packing and packaging shall be in accordance with Sections 5, Level C, of AS81824Tm.

5. This document takes precedence over documents reference herein.

• Tm AS81824 is a trademark of SAE